External combustion engine

Explore the principles and mechanics of external combustion engines, highlighting their historical significance and applications in various industries, such as power generation and transportation.

External Combustion Engine

Burning fuel produces heat. Steam is a form of energy. Mechanical energy is generated by applying thermal energy to the engine cylinder. The job of an engine is to convert thermal energy into mechanical energy. This transformation of energy requires a medium. In an internal combustion engine, liquid or gaseous fuel is burned inside the cylinder, and the resulting burnt gas sets the piston in motion by applying pressure directly to it. As a result, mechanical energy is generated.

However, solid fuel inside the cylinder is not usable. Therefore, steam is produced by heating water with the heat generated by burning fuel in a separate furnace. The water vapor produced is called steam. Using this fluid as a working medium in an external combustion engine is essential.

In systems where steam is generated, the equipment used is called a boiler, which is placed above the furnace. As a result, water evaporates due to the furnace heat. Depending on the quality of the steam produced, it is used in turbines or steam engines. The quality of steam depends on the amount of condensed water particles it contains. If no condensed water particles are present, the steam quality is 100%. Steam quality can be expressed as the dryness fraction. If a wet steam contains ms grams of dry steam and mw grams of water, then the dryness fraction of the steam is:

(x) = Weight of dry portion of steam/ Gross weight of wet steamer

Or x = ms/mw + ms

Steam can be divided into three categories based on quality: wet steam, dry saturated steam, and superheated steam.

Wet Steam:

Steam that contains condensed water particles is called wet steam. It is not suitable for use in an engine because the water particles can accumulate and damage engine parts.

Saturated Steam:

If the condition of dry steam at a certain temperature is such that it begins to condense with a slight decrease in temperature, then it is called dry saturated steam at that temperature. This steam is also not suitable for engine use.

Superheated Steam:

If dry steam is further heated at constant pressure, it is called superheated steam. Only superheated steam is suitable for use in external engines.

Differents between external and internal engine

Internal combustion engine:

- Occupies less space.

- Light in weight.

- The speed of this engine is relatively high.

- Combustion of fuel takes place inside the engine.

- Diesel or petrol is usually used as fuel.

- No fuel is consumed when the engine is off.

- Can be turned on and off instantly.

- Combustion of fuel in the engine cylinder generates very high temperature.

- Cooling system required.

- This engine is single acting.

- The temperature of expelled burnt gas is about 300°C.

- High thermal efficiency.

- No need for boiler, furnace, condenser etc.

External combustion engine:

- Takes up more space.

- Relatively heavy in weight.

- The speed of this engine is comparatively low.

- Combustion of fuel takes place outside the engine.

- Solid, liquid or gaseous fuels can be used to generate steam.

- Fuel combustion is not stopped even if the engine is stopped for a short time.

- Since it takes time to generate steam, it takes more time to turn it on and off.

- Operates at relatively low temperatures.

- No need for cooling system.

- Most are double acting engines.

- The temperature of the expelled steam is relatively low.

- Low thermal efficiency.

- Boiler, Furnace, Condenser etc.

Types of Outboard Engines (Types of E.C. Engines):

External combustion engines are mainly of two types:

- Steam Engine

- Steam Turbine

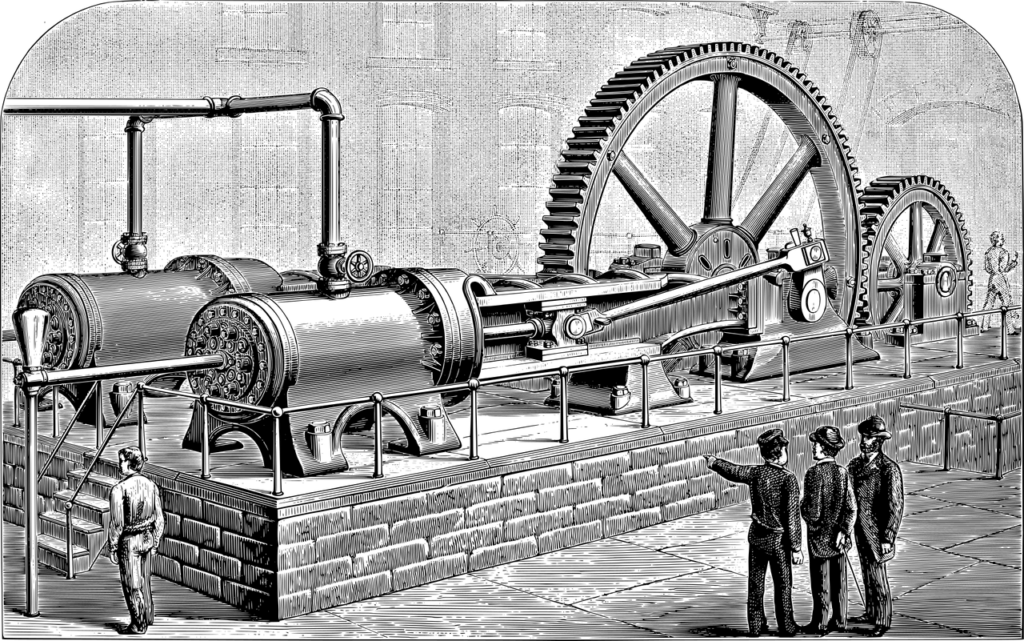

Steam Engine:

A steam engine is a reciprocating engine in which steam inside the cylinder raises the pistons, imparting rotational motion to the crankshaft and flywheel.

Main parts of steam engine are-

- Piston (P)

- Cylinder (C)

- Piston Rod (PR)

- Connecting Rod (CR)

- Crankshaft (S)

- Fly Wheel (F)

- Eccentric (E)

- Eccentric Rod (ER)

- Valve Rod (VR

- D-slide valve (V)

- Steam room (R)

- Crosshead (H)

- Stuffing box. (B)

- Cylinder Chamber (M)

- Crank Case (A)

Working Process External Combustion Engine

High-pressure superheated steam from the boiler continuously enters the steam chamber. The piston is connected to the crankshaft through a connecting rod and piston rod. Under steam pressure, the piston moves inside the cylinder.

When the piston is up, the D-slide valve connects the upper steam intake passage to the steam chamber. As a result, steam enters the cylinder above the piston, pushing it downwards. At this time, the lower steam passage is connected to the exhaust passage, allowing the lower chamber steam to escape.

Just before the piston reaches the bottom end, the lower steam passage is connected to the steam chamber through a V-slide valve. As a result, the steam coming from below pushes the piston upwards. At this time, the upper steam passage connects with the exhaust passage, discharging the upper chamber steam. The D-slide valve controls the flow of steam with the help of an eccentric.

The piston rod transfers power to the crankshaft through the connecting rod, allowing it to move the piston inside the cylinder. As a result, the rotation speed of the crankshaft and flywheel is achieved.

Uses of Steam Engine:

The steam engine, invented by James Watt, was first used to drive trains, primarily as a locomotive engine. Currently, with the widespread adoption of diesel engines, the use of steam engines has become limited. Steam engines are also used in rice mills, jute mills, and yarn mills.

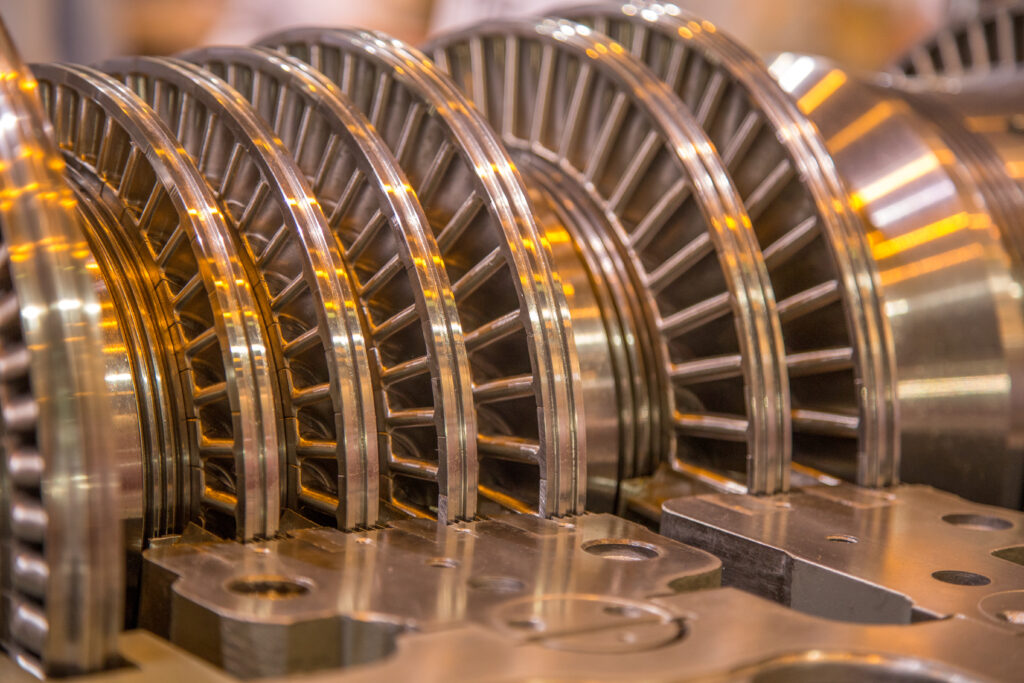

Steam Turbine:

A steam turbine is a type of machine that is driven by steam pressure and powers connected machinery. Its primary use is in steam power plants, where steam generated in the boiler drives the steam turbine. Generally, electricity is produced by connecting a generator to the turbine, which is thus considered a prime mover.

Types of Steam Turbines:

Steam turbines are mainly of two types:

- Impulse or Velocity Turbine

- Reaction or Pressure Turbine

Impulse Turbine:

This type of turbine is driven by the kinetic energy of steam, and thus is also called a velocity compound turbine. In an impulse turbine, steam flows through a nozzle and strikes the turbine blades with force, causing the turbine rotor to rotate. As the rotor is rigidly attached to the shaft and supported by shaft bearings, the shaft rotates as well. Electricity is generated by connecting a generator to this shaft. This turbine operates on the impulse energy of the steam, hence the name “impulse turbine.”

Reaction Turbine:

A turbine that is driven by the reactive force or back thrust of steam is called a reaction turbine. Imagine a rotor with several nozzles and a steam supply inside it. As steam exits through these nozzles, the back thrust of the steam causes the rotor to rotate in the opposite direction to the steam’s flow. This is the working principle of reaction turbines. In practice, impulse-reaction turbines, which combine both impulse and reaction principles, are more commonly used.

Uses of Steam Turbine:

Steam turbines are widely used as prime movers in steam power plants. They are also utilized in water vessels, steamers, and in industries such as jute mills, yarn mills, cloth mills, and pharmaceutical factories.