Bad spark plugs symptoms

Understanding the Impact of Bad Spark Plugs on Vehicle Performance: Analyze how faulty spark plugs can affect overall vehicle performance, including acceleration, fuel consumption, and emissions. Offer advice on how to address these issues and the long-term advantages of keeping spark plugs in good condition.

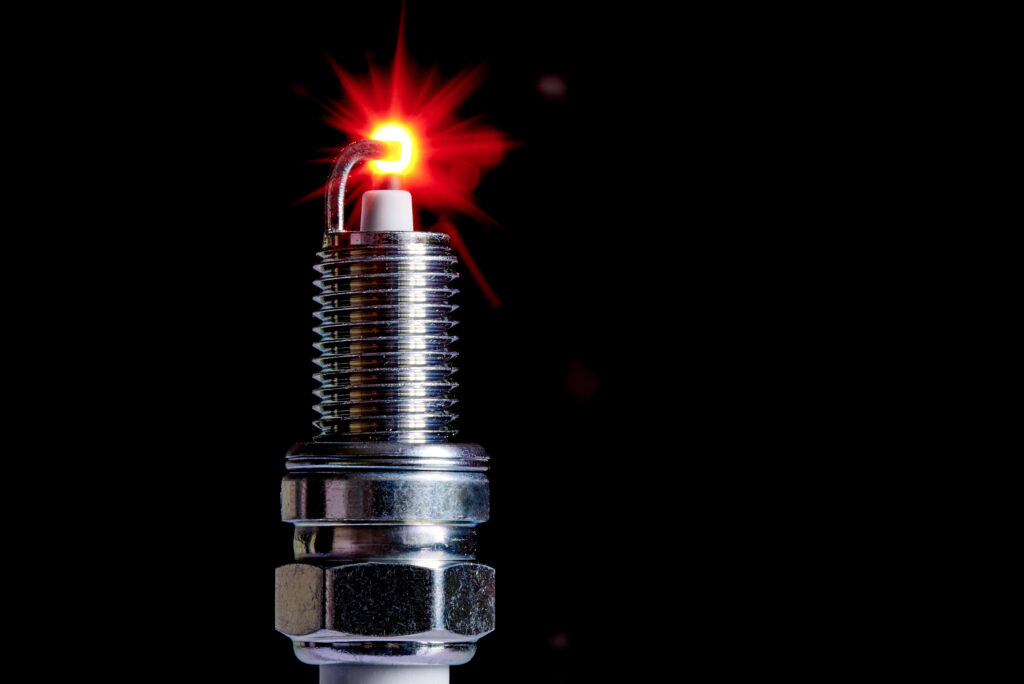

What is spark plug? How does a spark plug work? The 6 or 12 volts from the storage battery are converted to a voltage of 21,000 to 25,000 volts by the ignition coil, and the spark occurs when the circuit is completed by the opening and closing of the CB point.

Spark Plug: It is a special component of the petrol engine and ignition system. Its purpose is to produce a spark in the combustion chamber at the end of the compression stroke, igniting the air-petrol mixture and actively contributing to the production of thermal energy. The spark plug consists of two main units:

(a) Non-conductive core unit (Core insulator assembly)

(b) Shell unit (Shell unit)

The core unit of the spark plug is made of a non-conductive material that can withstand the high-voltage electrical power, high heat, and pressure within the combustion chamber. The central electrode is connected to the interior of this unit, with the terminal wire attached to the upper end of the electrode. This unit insulates the shell unit, preventing any reaction to high voltage and heat from reaching the shell. The shell unit serves as the housing or casing for the non-conductive core unit and is constructed from steel. Its ground electrode is attached to the lower part by metal bonding. The top part of the shell resembles a hexagonal nut, which is attached to the cylinder head or side using a threaded hole and a wrench. The gap between the central and ground electrodes of a spark plug is 0.6 mm to 1 mm.

Bad spark plugs symptoms

1. Engine misfires when hot.

Causes of fault

a) Breaker arm spring is loose, resulting in swinging of CB point.

(b) Fault in ignition coil or condenser.

(c) CB point defective.

(d) Corroded or broken breaker plates.

Remedy or repair

a) Spring is bent or altered.

(b) Test both and if necessary.

(c) Both sides are subject to examination and modification if necessary.

(d) Check, clean and correct clearance of CB point required.

(f) The breaker needs to be opened, repaired or replaced.

2.Engine does not start in wet weather.

Causes of fault

(a) The non-conductive material of the Spark Plus is dirty and wet.

(b) The secondary of the ignition coil absorbs or wets its oil.

(c) Moisture on distributor rotor and underside of cover.

(d) Moisture and dirt on the outside of the coil at the secondary terminal.

Remedy or repair

(a) Dirt on the spark plug should be cleaned by rubbing it with a cloth.

(b) It is necessary to sprinkle or coat the secondary wire with a cloth soaked in kerosene or carbon tetrachloride and wiped and cleaned.

c) Accessories including rotors should be wiped with a clean and dry cloth.

(d) Must be wiped off with a clean and dry cloth.

3.CB points occasionally burn out and need to be replaced.

Causes of fault

a) Condenser is faulty.

b) Delay in condenser lead connection and grande fault.

c) CB point too oily.

(d) The spacing of CB points is too short.

(e) Generator voltage is too high.

Remedy or repair

a) Modifications and additions are required as per specification.

b) Condyle connection needs correcting.

(c) Cleaning required.

(d) Gap correction is required as per manufacturer’s instructions.

(e) Monitoring and rectification of generator supply is necessary.

4.Engine cranks normally but does not start.

Causes of fault

(a) Storage battery is uncharged.

(b) Primary circuit of ignition coil open.

(c) CB point burned.

(d) Ignition timing error is associated.

(e) Condenser has a faulty.

(f) Defective spark plug

Remedy or repair

a) Charging is necessary.

b) Connections of CB points, ignition coils etc. need to be monitored and rectified.

(c) New and functional CB point connection on modified floor. Have to do

(d) Condenser subject to change without repair.

(e) Clean and modify as necessary.

5.The engine runs but is missing a cylinder.

Causes of fault

(a) The spark plug of said cylinder is intact.

(b) Distributor, cap, lead etc. defective.

Remedy or repair

(a) Spark plugs should be cleaned and replaced if necessary.

(b) To be repaired.

6.Engine runs but misses various cylinders.

Causes of fault

(a) Condyle defective.

(b) CB points damaged, soiled and Error in its coordination.

(c) Ignition coil weak.

(d) Defective spark plug.

(e) Malfunction in ignition advance mechanism.

Remedy or repair

(a) Condenser must be changed.

(b) To clear or change CB points.

(c) Change the ignition coil.

d)Spark plugs need to be changed at specified intervals.

e) Inspect and repair if necessary.

7 condition of affecting in spark plug functioning

The spark plug is an electrical component of the petrol engine that creates sparks from high voltage across two electrodes. Spark plugs used in modern automobiles have a gap between the center and ground electrodes of 0.6 mm to 1 mm. A high voltage applied to the center electrode of a properly functioning spark plug can produce a spark under the following conditions:

(1) When a high voltage (20,000 to 47,000 volts) is applied to the center electrode, if there is an appropriate gap between its two electrodes, a spark will occur in the spark plug gap as that voltage jumps to ground.

(2) If there is no discharge in the high-tension line, the voltage can reach the center electrode and cause sparking.

(3) If the air and fuel line filters are in good condition and the fuel is of good quality, dirt will not easily accumulate in the spark plug gap. As a result, it can spark properly.

(4) With prolonged use and wear, the gap between the spark plug electrodes widens. Therefore, this gap should be monitored and adjusted periodically.

(5) If the CB point of the distributor is not functioning properly, it affects the spark plug. Thus, the CB point gap is checked and cleaned regularly, and its gap size adjusted if necessary.

(6) The function of the spark plug is influenced by its size, whether large or small. For example, using a larger spark plug increases the engine’s compression ratio (C.R.), whereas a smaller one requires regular replacement to maintain efficiency. Otherwise, a worn spark plug can negatively affect the entire engine.

(7) The spark plug connection must be tightly screwed; otherwise, charge may leak into the combustion chamber.

11 proven ways to cleaning spark plug

- Spark plugs should be removed with a spark plug wrench.

- If there is oil in the spark plug gap, brush it with a petroleum solvent and dry it thoroughly.

- For sandblasting, insert the spark plug into the correctly sized rubber adapter. After turning on the compressed air line, perform sandblasting by activating the sandblast switch.

- After sandblasting, use only air blasting to remove any sand particles.

- Grade seals should be cleaned with a fine wire brush.

- The electrode surface should be filed with a special type of point file.

- The gap should be set according to the dimensions specified by the manufacturer using a bending tool and a round gauge.

- To perform a spark test, insert the spark plug into the spark plug tester hole, rotate the spark plug by hand, and turn on the compressed air line.

- After pressing the electrical connection of the tester, the spark pattern can be observed on the polished metal mirror.

- If a dark blue spark is produced, the spark plug is functioning properly.

- Spark plugs should be installed in the engine using gaskets. If the pressure is too high, the electrode may bend and the gap setting could change. The spark gap is usually 0.6 to 1.0 mm.

How to adjust of CB point gap of spark plug.

Proper opening and closing of CB points are necessary to achieve good ignition performance. Therefore, correct adjustment is very important. In the closed state, electric flux is generated in the primary winding of the ignition coil, and in the open state, the flux in the primary winding collapses, generating high voltage in the secondary winding. Flux density depends on the amount of current in the primary coil. The voltage of the secondary winding is dependent on the flux density of the primary winding. So, a proper amount of CB point contact is required. The degree to which the CB point is closed during the rotation of the distributor shaft is called the dwell angle. The smaller the gap at the CB point, the greater the dwell angle. If the CB point gap is less than required, high current flow causes the CB point to burn out; if the CB point gap is too large, the spark is weak because sufficient high voltage cannot be generated in the ignition coil.

There are three methods of checking the CB point gap:

- Filler Gauge Method: In this method, open the rotor cap and turn the distributor shaft so that the rubbing block of the lever arm is on the high part of the cam lobe. In this condition, the CB point will be open, and the gap should be measured by inserting the filler gauge between the CB points. Then, loosen the lock screw and turn the eccentric to adjust the correct gap. This method is applicable only to good CB points.

- Dwell Angle Meter Method: The CB point and filler gauge method are not effective after the engine has been running for a long time. In that case, the dwell angle is measured by a dwell meter. For a 6-cylinder engine, a 360° rotation of the rotor shaft equals 60° per cylinder. Thus, 60% of the angle, i.e., 36°, is the dwell angle. If the dwell angle is greater than this, the CB point gap should be increased; if the dwell angle is less, the CB point gap should be reduced.

- Window Method: This is not a standalone method but complements the other two methods. In this case, the adjustment screw can be seen and adjusted by simply removing the window without opening the rotor shaft. The CB point gap is usually between 0.3 mm and 0.5 mm.