How to reduce diesel engine noise

Learn how to minimize diesel engine noise with our comprehensive guide. Implement proven techniques for a quieter operation and enhanced driving experience.

Reducing diesel engine noise involves several strategies. First, regular maintenance, such as tuning and replacing worn parts, ensures optimal engine performance and reduces unnecessary noise. Installing high-quality engine mounts can dampen vibrations, minimizing transmitted noise. Using soundproof materials, like acoustic foam or insulation blankets, around the engine bay also helps. Opting for a well-maintained exhaust system with mufflers reduces exhaust noise significantly. Upgrading to quieter injectors or fuel systems can lower combustion noise. Ensuring proper lubrication reduces mechanical noise from friction. Finally, operating the engine at lower RPMs and avoiding sudden accelerations can help keep noise levels under control.

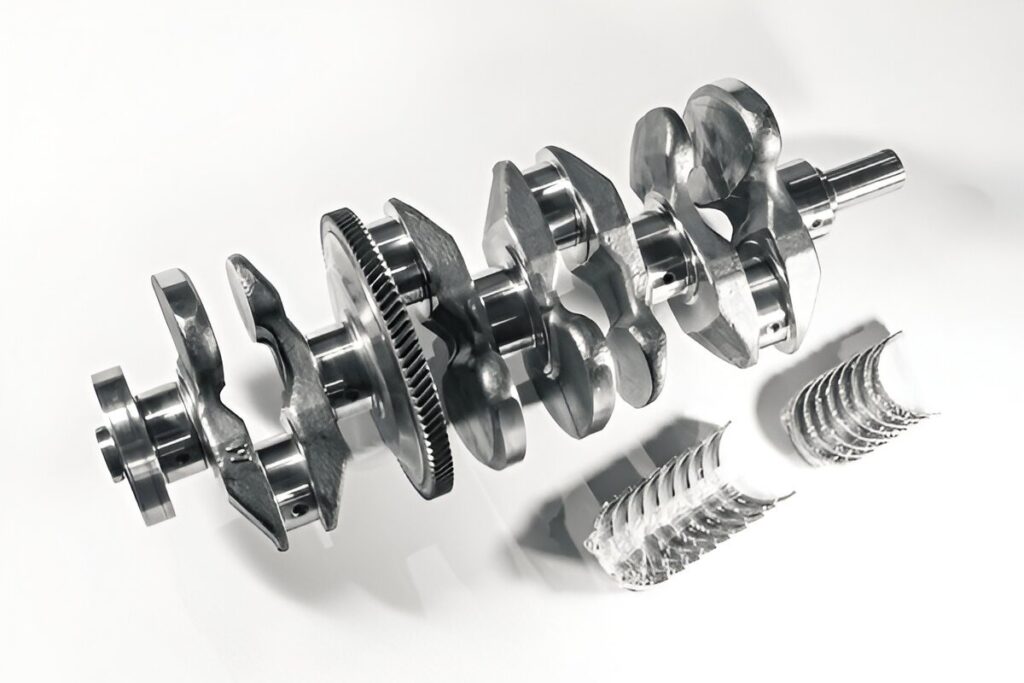

1.The main bearing makes noise

Because

(a) Inadequate oil supply.

Remedy:

Check the oil level and add oil if necessary. The oil pump relief valve should be checked for proper functioning. Repair or replace as necessary.

Because

(b) Low oil pressure.

Remedy:

Check the oil level and investigate all possible causes of low pressure. Take appropriate action accordingly.

Because

(c) Oil is diluted.

Remedy:

Change the oil and fill the crankcase with oil of the correct viscosity or service rating.

Because

(d) Bearing clearance is excessive.

Remedy:

Check the bearing clearance and take necessary corrective action.

Because

(e) Crankshaft end play.

Remedy:

Corrosion of main bearings and flanges should be checked, and necessary action should be taken.

Because

(f) Main bearing journals are corroded.

Remedy:

Grind the journals or replace the crankshaft.

Because

(g) Flywheel or torque converter is loose.

Remedy:

Tighten to the proper torque.

2. Connecting rod sounds

Because

(a) Inadequate oil supply.

Remedy:

Check the oil level and add oil if necessary. The oil pump relief valve should be checked for proper operation and repaired or replaced if needed.

Because

(b) Low oil pressure.

Remedy:

Investigate the causes of low oil pressure and take appropriate action.

Because

(c) Oil is diluted.

Remedy:

Drain the oil and refill the crankcase with oil of the correct viscosity or service rating.

Because

(d) Excess bearing clearance.

Remedy:

Measure the bearing clearance and make necessary corrections.

Because

(e) Connecting rod journals are out of round.

Remedy:

Perform journal grinding.

Because

(f) Connecting rod is bent.

Remedy:

Replace the connecting rod.

3. Noisy valve

Because

(a) Oil level is too low or too high.

Remedy:

Adjust the oil level to the correct level.

Because

(b) Oil is thin or diluted.

Remedy:

Drain the oil and refill the crankcase with oil of the correct viscosity or service rating.

Because

(c) Oil pressure is low.

Remedy:

Investigate the cause of low oil pressure and take appropriate action.

Because

(d) Dirt on valve tappets.

Remedy:

Clean the valve tappets.

Because

(e) Push rod is bent.

Remedy:

Replace the defective push rod.

Because

(f) Rocker arms are corroded.

Remedy:

Replace the defective rocker arms.

Because

(g) Tappets are corroded.

Remedy:

Install new tappets.

Because

(h) Valve guides are corroded.

Remedy:

Ream the valve guides to fit new valves with oversize stems or replace the valves and guides as necessary.

Because

(j) Excessive run-out on valve faces and seats.

Remedy:

Grind the valve faces and seats.

4. Regular clicking

Because:

Valves and lifters.

Remedy:

Readjust valve clearance or replace noisy hydraulic valve lifters.

5. Ping noise under load or acceleration.

Because:

Use of low-octane gasoline, detonation, carbon buildup, advanced ignition timing, or engine backfire.

Remedy:

Use higher octane fuel, remove carbon deposits, and adjust ignition timing.

6. Light knock

Because:

Corroded connecting rod bearings or crank pins, incorrect alignment of connecting rod, or low oil.

Remedy:

Replace bearings, service the crank pin, realign or replace the connecting rod, and add oil.

7. Light, metallic double sound heard during idling

Because:

Corroded piston pin, seized pin, or lack of oil.

Remedy:

Service the pins and bushings, and add oil.

8. Chattering or knocking during acceleration

Because:

Corroded ring or cylinder wall, reduced ring tension, or broken ring.

Remedy:

Service the cylinder wall and replace the ring.

9. Dull, heavy metallic knock under load or acceleration, especially when cold

Because:

Main bearing wear, thrust bearing wear, clutch engagement noise, or hard acceleration.

Remedy:

Service or replace the crankshaft and bearings.

10. Hollow, muffled bell-like sound (engine cold)

Because:

Piston slap due to corrosion, piston skirt collapse, excessive clearance, misaligned connecting rod, or oil shortage.

Remedy:

Replace pistons, service the cylinder wall, and add oil.

11. Miscellaneous noises

Because:

Loosely coupled accessories such as alternator, horn, oil pan, front bumper, or water pump.

Remedy:

Ensure all mounting points are tight.

Conclusion: To effectively reduce diesel engine noise, implementing soundproofing measures, utilizing noise-dampening materials, and maintaining the engine properly are essential strategies. These approaches not only enhance comfort but also contribute to a more environmentally friendly operation.