What does a radiator do in a car? Water cooling system in engine

Discover the essential role of a car radiator in maintaining engine temperature. Learn how it works and why it’s crucial for vehicle performance and longevity.

Cooling System of car:

If the high temperature generated by the combustion of fuel in the engine’s combustion chamber is not removed, engine parts will burn. The combustion temperature of a diesel engine is about 2000°C and a petrol engine about 1200°C, while the recrystallization temperature of iron is 1000-1530°C. To avoid these high temperatures, heat is managed using a cooling system, and the engine operates at around 80°C.

Necessity of Cooling System of car:

- This method protects the engine from overheating and burning, thereby maintaining a normal engine temperature.

- Combustion of the air and fuel mixture in the combustion chamber of the cylinder produces a temperature of 1100°F to 4500°F. This temperature overheats the cylinder head, cylinder walls, and pistons. As a result, the oil film that exists between the cylinder walls and the piston may dry out due to heat, and the cylinder and piston may become damaged. An engine cooling system is used to prevent this condition.

- The engine cooling system absorbs 30% to 35% of the heat generated in the engine, reducing the heat to protect the engine from overheating and helping it to run normally.

- When the engine is running and its temperature is low, it does not need to be cooled. At this time, the engine cooling system stops. This method is used to maintain the normal temperature of the engine.

- Small engines are air-cooled, large engines are water-cooled, and most engines are both air- and water-cooled. When this procedure is followed, the combustion, lubrication, starting, and fueling of the engine can all function properly.

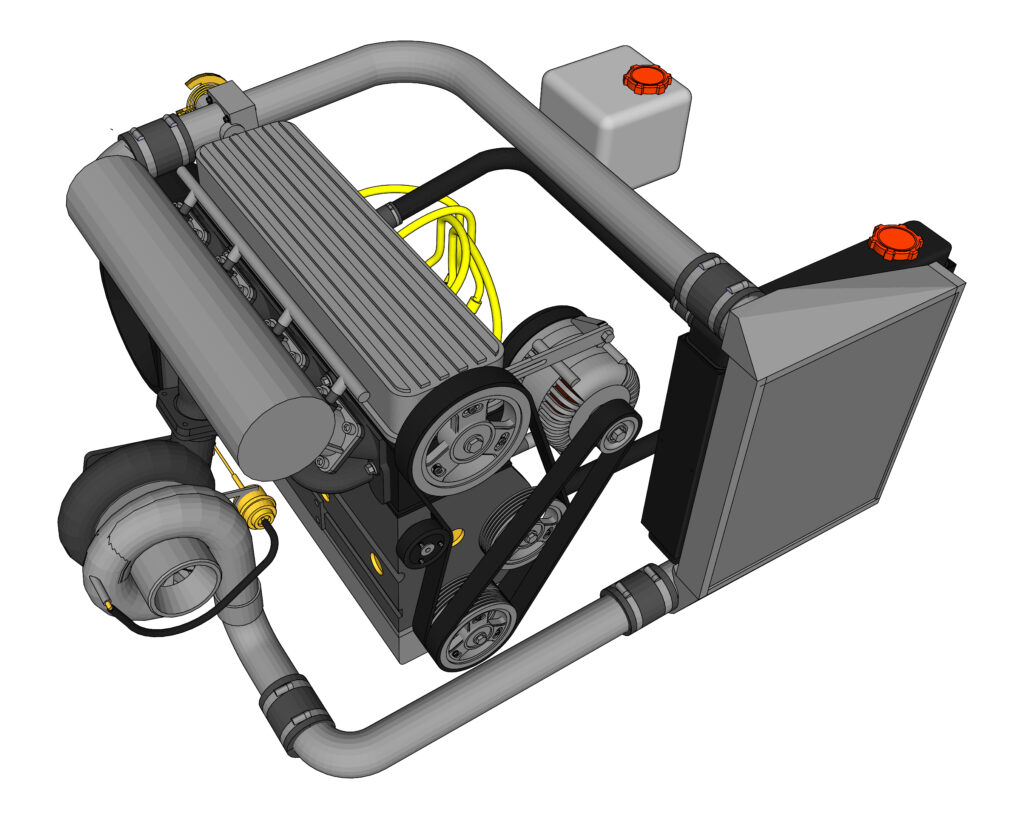

Water Cooling System in Engine

The method in which water is used as the cooling medium is called the water cooling method, also known as an indirect or liquid cooling system. The water cooling system consists of a radiator, water jacket, cooling fan, water pump, hose pipes, etc. Water circulates in a water jacket around the engine cylinder, cooling the cylinder head through water flow. When the engine is running, the water pump and cooling fan are activated. Because of this, the water in the jacket is drawn in by the pump and pushed through the upper hose pipe to the radiator. Air from the front of the engine catches the fins of the radiator, where it is cooled by air from the cooling fan, and flows through the lower hoses back into the engine jacket. In this way, the water in the water cooling system continuously circulates and cools the engine while it is running. A thermostat valve in this system controls the engine temperature in colder regions by turning the flow of cooling water on and off. The radiator water in these motor vehicle engines begins to circulate at 160°F to 168°F. When the temperature reaches 180°F, the valve opens fully, allowing the water in the jacket to cool in the radiator and return to the jacket. 160°F is considered the engine’s operating temperature, and below this temperature, the engine is cold, so the thermostat valve remains closed.

In countries located in temperate zones, the use of antifreeze solution and thermostat valves may not be necessary. The water cooling system is commonly used to cool the engines of jeeps, cars, buses, trucks, ships, and trains. In this method, an overflow tank or overflow pipe is connected to a reservoir above the radiator, allowing excess water (expanded due to heat) to flow into this reservoir or through the pipe.

Construction of Cooling System Components:

Water Pump: A centrifugal pump is used to circulate cooling water in water-cooled engines. This pump is used in pressurized or pump-type cooling systems. It is centrally connected to the cylinder block and driven by the cooling fan belt. A water pump is also used in V-shaped engines and other engine types.

The impeller operates within the pump casing, generating centrifugal force when the engine is running. This force pushes cold water from the radiator to the water jacket of the cylinder block and head. The water pump consists of an impeller, impeller blades, a container, an inlet, a volute chamber, etc.

Water Jacket: A water jacket is used for water cooling in medium and high-power engines. Water flow areas are designed around valve guides to cool the engine valves. In some engines, the water jacket and supply pipe are vertically placed between the cylinder and valve ports. The water pump supplies water to the valve stem and cylinder jacket through the lower hose pipe, where it absorbs heat and then travels to the radiator through the upper hose pipe.

The jacket’s cooling water absorbs heat generated in the valves, combustion chamber, and cylinders. As it enters the radiator, the water is cooled by natural airflow and fan air, then recirculates back into the jacket. The water jacket should be cleaned regularly, and dirty water can be drained through a hole located at the bottom of the cylinder block.

Radiator: A radiator acts as a water reservoir to cool a water-cooled engine. It is attached to the front of the vehicle. Heated water flows from the water jacket into the radiator, where it cools by passing over numerous radiator fins and is aided by airflow and the cooling fan before re-entering the water jacket.

The radiator consists of an upper inlet receptacle, a lower outlet, and other components. Based on shape, radiator cores are generally classified into two types:

- Tubular type radiator: Consists of numerous round or flattened metal tubes, with the ends welded to the upper and lower receptacles.

- Cellular type radiator: Has a narrow passage formed by pressing a sheet metal block into the radiator. The core extends from the upper to the lower receptacle, and is welded to a thin copper sheet.

Thermostat: As discussed earlier, the thermostat controls the temperature of the engine’s cooling water. It prevents the cooling water from circulating until a certain temperature is reached. Thermostats are generally classified into two types:

- Bellows type thermostat

- Bimetallic type thermostat

The thermostat is usually attached to the cylinder head at the junction of the cooling water discharge pipe and radiator or inside the hose pipe. V-shaped engines use two thermostat valves, one for each cylinder bank. Bellows-type valves contain a liquid that rapidly vaporizes when heated, creating pressure that opens the valve. As the engine cools, the vapor condenses, reducing pressure and closing the valve. The thermostat valve remains closed when the water is between 140°F and 160°F.

In automotive radiators, thermostats typically begin to open between 150°F and 180°F, and are fully open at 200°F. High-temperature thermostats are used in colder climates to ensure efficient operation. In Bangladesh, which is a temperate country, engine thermostats include components like valves, coils, casings, etc.

Cooling Fan: Air from the front of the vehicle and a cooling fan at the rear are used to cool the water in the radiator. The fan is driven by pump pulleys, generator drive pulleys, separate fan-driven pulleys, or directly by the crankshaft pulleys. A V-belt driven fan is fitted into a V-shaped groove on the anti-vibration wheel at the front of the engine crankshaft.

The fan’s function is to cool the hot water in the radiator core by moving air over it, thereby dissipating heat into the atmosphere. In rear-mounted engines, the air circulation system of the fan works in the opposite direction, where the fan is known as an “air pusher fan.” Fan speed depends on engine speed.

Radiator Pressure Cap: As temperature increases, so does the pressure of liquids and gases. When the cooling water’s boiling point rises, its pressure also rises; conversely, if pressure decreases, the boiling point lowers. At sea level, with an air pressure of 14.7 pounds per square inch (1.01 kg/cm²), water boils at 212°F (100°C). When air pressure decreases, so does the boiling point, which can cause water loss from the radiator when ascending hills. The cap on the radiator is called a pressure cap.

Purpose of Using Antifreeze Solution in Engines for Cold Climates:

The substance or solution mixed with cooling water in engines used in cold climates, which prevents the cooling water from freezing and ensures it remains in liquid form, is called an “antifreeze solution.”

The purposes of using an antifreeze solution are as follows:

- Antifreeze mixed with cooling water prevents it from freezing at 32°F or 0°C.

- Air is mixed with cooling water, which prevents freezing and the risk of cylinder block rupture by ensuring water does not accumulate and expand when in use.

- The cooling water flows and functions normally at any temperature, and the antifreeze prevents the accumulation of dirt and rust.

- When dissolved in water, the antifreeze does not significantly lower the boiling point of the liquid.

- The antifreeze solution remains effective even after extended use.

- It does not cause any corrosiveness, acidity, or solubility reactions that could harm cooling system components.

- The cost of using antifreeze is minimal compared to its benefits.

In water-cooled engines, antifreeze solutions like methyl alcohol (methanol), synthetic wood alcohol, ethyl alcohol, and ethylene glycol are commonly used. Ethylene glycol, in particular, does not produce any gas and has a high boiling point of 300°F, commonly known as Prestone or Zerex, which effectively prevents water from freezing.

Antifreeze solutions containing substances like salt, lime or calcium chloride, soda, sugar, honey, or petroleum are harmful to the cooling system.