How does supercharger and scavenging improve engine efficiency?

Uncover the benefits of supercharger and scavenging in engine efficiency. This process optimizes airflow, enhancing combustion and contributing to superior engine performance.

What is supercharging?

Supercharging is a process by which an extra charge (a petrol-fuel mixture or fresh air) is introduced into the intake stroke of an engine.

Purposes of supercharging:

- The engine output is increased by sending an excess air-fuel mixture to the intake stroke of a petrol engine.

- The engine output is increased by sending extra clean air to the intake stroke of a diesel engine.

- This mechanism ensures that even when a relatively low vacuum is achieved in the intake stroke, excess charge can still enter the engine.

- Supercharging is an efficient method used in high-speed automobiles and aircraft engines.

- By using this method, the weight and size of the engine can be reduced.

- In hilly areas where air pressure is lower, this method is more effective for providing extra charge and achieving extra power.

Effect of Supercharging on S.I. and C.I. Engine Performance

The requirements of supercharging systems in S.I. (petrol) engines are as follows:

- This method provides an additional air-fuel mixture in the intake stroke of the S.I. engine.

- It plays an active role in increasing the performance of the engine.

- It supplies more air and fuel mixture to the engine for increased power, especially when driving in hilly areas.

- This system compensates for low vacuum levels in the cylinders at high engine speeds, ensuring optimal performance.

- By using this method, the size of the engine can be reduced.

- This process enables smooth emission of combustible gases, as it utilizes excess base gas produced by the combustion of additional fuel.

- Excess air or charge provides additional oxygen, which aids in efficient combustion.

The requirements of supercharging in C.I. (diesel) engines are as follows:

- Supercharging is used to introduce extra air into the intake stroke of a C.I. engine.

- This system increases engine power by supplying additional air or charge, particularly when driving in hilly areas.

- By using this method, the performance of the engine is enhanced.

- Engine power can be increased by 20% to 50% through the supercharging method.

- This method reduces the size and weight of the engine.

- It helps the engine handle overloads more effectively.

- The economic benefit of supercharging outweighs the additional cost of implementing the system.

The device that activates the supercharging process is called a supercharger. Without a supercharger, the vacuum created in the intake chamber of the engine cylinder allows as much charge as possible to enter the cylinder based on the vacuum. In supercharged engines, 20% to 50% additional charge can enter the cylinders due to the combined effects of vacuum, atmospheric pressure, and the supercharger’s boost.

Atmospheric pressure is typically 1.01 kg per square centimeter (16.7 pounds per square inch). In engines using a supercharger, an additional charge of 1.5 kg per square centimeter (5 to 6 pounds per square inch above atmospheric pressure) is introduced into the engine. This extra charge, combined with additional oxygen, enables the engine to produce more power.

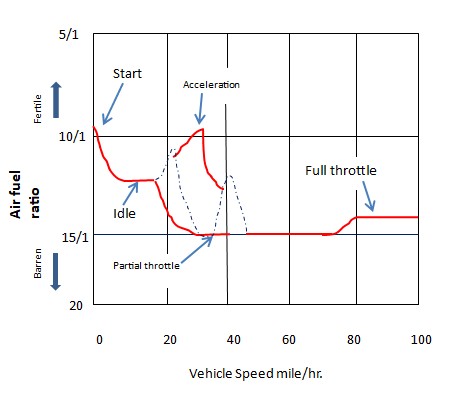

As shown in the figure, the engine does not use the same air-fuel mixture ratio at all speeds and loads. A rich mixture is used when the engine starts, a medium-rich mixture during normal operation, and a lean mixture at high speed. However, if the lean mixture is used for an extended period, the engine loses thrust. Additionally, when the engine operates in hilly areas, impure mixtures do not enter the engine due to reduced air pressure.

To address these issues, a supercharger injects charge into the engine when the air-fuel mixture flow follows conventional rules based on vehicle speed. This injection enhances the engine’s load capacity and speed. The supercharger prevents prolonged use of lean mixtures, ensuring that vehicle handling and acceleration remain unaffected.

By sending additional charge to the engine, the supercharger creates a favorable environment for smooth combustion. It aids this process by introducing extra oxygen (O₂) along with the charge. After combustion, the exhaust gases are expelled efficiently through scavenging. As a result, supercharging improves engine response and overall performance.

What is Scavenging?

Scavenging is the process of removing burnt gases from the S.I. (petrol) or C.I. (diesel) engine and releasing them into the atmosphere.

Scavenging in S.I. Engines

The requirements for scavenging in S.I. (petrol) engines are as follows:

(a) This process removes burnt gases from the combustion chamber of the petrol engine and releases them into the atmosphere. It is primarily used in two-stroke petrol engines.

(b) It opens the exhaust port from the combustion chamber and expels burnt or unwanted gases, allowing fresh charge (a mixture of air and fuel) to enter the combustion chamber at the beginning of the next stroke. This increases engine power.

(c) If scavenging does not function properly, burnt gases would remain in the combustion chamber, causing the engine to stop.

(d) During scavenging, some of the charge in a petrol engine is expelled along with the burnt gases due to valve overlap. While this causes financial loss, the process remains beneficial for engine performance.

Scavenging in C.I. Engines

The requirements for scavenging in C.I. (diesel) engines are as follows:

(a) This process is generally used in two-stroke diesel engines, where it proves to be highly efficient.

(b) It removes burnt gases from the combustion chamber and expels them into the atmosphere.

(c) By clearing unburnt gases, fresh charge (clean air) can enter the combustion chamber at the beginning of the next stroke.

(d) This increases engine power.

(e) If scavenging does not function properly, burnt gases remain in the combustion chamber, leading to engine shutdown.

(f) In diesel engines, scavenging causes less harm as only clean air (not a fuel mixture) is expelled during valve overlap. This results in a slight loss of engine power but avoids financial loss.

Supercharging and scavenging process (Methods of supercharging and scavenging): Supercharging is a process by which the intake stroke of a petrol engine Excess air and fuel mixture enter the cylinder and clean air is introduced into the intake stroke of the diesel engine. This increases both the performance and efficiency of the engine and due to which the engine can carry more load and helps in increasing the speed. In the case of petrol engines, a turbocharger is used between the engine and the carburetor in the supercharging process as shown. The air cleaner cleans the atmospheric air and sends it to the carburetor. Carburetor prepares proper mixture of air and fuel. The turbocharger sends the vehicle’s excess air and fuel mixture to the engine in a vacuum from the carburetor.

On the other hand, scavenging is a process through which the burnt gas of a petrol or diesel engine is pushed out by a blower or scavenging pump at a pressure higher than atmospheric pressure. This removes the blockage in the combustion chamber and subsequently allows more air and fuel mixture to enter the combustion chamber and create an environment for combustion. This process acts as a draft and helps the engine achieve more power.

Operation of Supercharger and Turbocharger

Supercharger: A supercharger is a device driven by engine components such as bent gears, exhaust gas, or an electric motor. It increases engine efficiency by injecting extra charge into the intake stroke of the engine.

Conventional superchargers are classified into three main categories:

(a) Piston and cylinder type

(b) Positive rotary blowers

(c) Centrifugal type superchargers

Among these, positive rotary blowers and centrifugal superchargers are the most commonly used. This type of supercharger is generally found in two-stroke petrol or diesel engines. In diesel engines, it is used to supply additional fresh air to enhance combustion efficiency.

Typically, these superchargers are driven by the push of exhaust gases, contributing to better performance and power.

Turbocharger: A turbocharger is a type of supercharger that is driven by a common shaft connecting the compressor and turbine. It is also referred to as a turbo-supercharger because its structure is similar to a turbine. A turbocharger is a centrifugal-type supercharger.

In operation, the charge (either a mixture of air and petrol or clean air) coming from the compressor gains centrifugal force as it pushes against the vanes of the turbocharger. This force causes the charge to expand and flow into the intake stroke of the engine through a thick tube. The process in which the charge enters the engine cylinder under pressure from the turbo-supercharger is known as supercharging.

The main advantage of using a turbocharger over a blower is that the vanes of the turbocharger are larger than those of the blower. This allows the turbocharger to deliver the charge to the engine at a higher pressure, resulting in greater engine efficiency. By using a turbocharger, the efficiency and performance of the engine can be significantly increased.