Explore our comprehensive guide on troubleshooting engine lubricating systems. Learn key strategies to maintain optimal engine performance and reliability.

Engine Lubrication principles

When one part rotates between the other parts, the collision that occurs between them is called friction. For example, when an engine shaft rotates in its bearings, there is friction between the inside of the bearing and the outside of the shaft. Friction is classified into three categories viz.

(a) Dry friction: This friction occurs when two solid objects come into contact.

(b) Greasy friction: Friction produced between two rotating or moving parts made of solid metal in the presence of a lubricating substance is covered by this friction.

(c) Viscous friction: This friction occurs between sliding parts of engines or machinery.

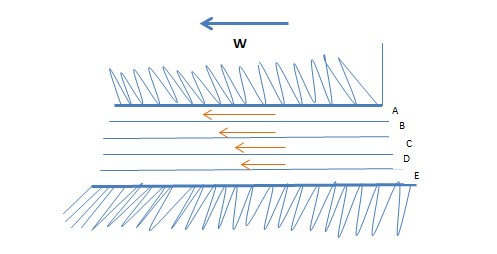

In dry, oily and sticky friction, lubricating substances such as grease, lube oil, etc., absorb the frictional heat in the molecules of the parts and prevent friction. This theory is called Principle of Lubrication or Molecular theory of friction. In Figure, A, B, C, D and E are five oil layers, W is the weight of the rotating parts, and the lower part is the fixed part. A helps to roll smoothly, the intermediate layers during friction heat and the E-layer maintains the smoothness of the fixed parts.

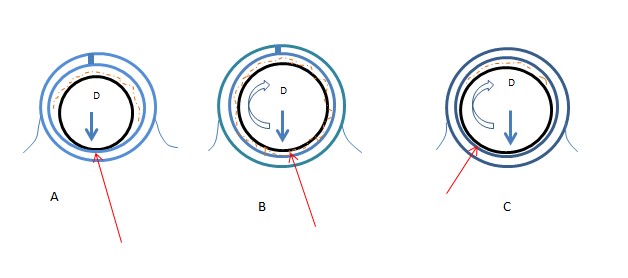

The figure shows the reaction of the oil screen between the rotating journal or shaft and bearing. In the figure “a” the shaft is stable, “b” the beginning of shaft rotation and “c” the shaft is rotating at full speed. Furthermore, b-high pressure areas, e-engine and shaft loads and lubrication oil inlets are shown.

So according to the theory of friction and lubrication, the lubricant maintains the smoothness between the rotating parts, prevents friction, the frictional heat gradually helps the parts to rotate smoothly.

A proper lubrication system is essential for that. So troubleshooting engine lubrication system is very important for the engine.

Troubleshooting engine lubricating system, Cause and remedy

The following explanation discusses troubleshooting engine lubrication systems in detail. Consequently, the root cause can be identified by looking at the symptoms. As a result, as time will be saved in solving the problem, economic benefits can also be gained.

1. Lubrication oil rises in the piston head.

Causes:

(a) Liner and oil scraper ring are corroded, weakened, or broken.

(b) The oil ring is fitted upside down.

(c) Excess oil is present in the crankcase.

Remedies:

(a) Replace the damaged ring. Inspect the cylinder for damage and replace the liner if necessary.

(b) Ensure the oil ring is installed correctly.

(c) Apply the correct amount of oil to the crankcase (in three parts, as required)

2. Lubrication oil becomes more expensive.

Causes:

(a) Excessive wear on piston rings or cylinder walls.

(b) Damaged gasket.

(c) Engine overheating.

(d) Leakage in oil pipes or a damaged oil seal.

Remedies:

(a) Replace corroded piston rings, liners, or other worn components.

(b) Replace the damaged gasket.

(c) Maintain the engine at a normal operating temperature and allow for adequate rest periods.

(d) Repair or replace leaking oil pipes and damaged oil seals.

3. The lubrication oil shows less viscosity or effectiveness.

Causes:

(a) The oil is too thin (incorrect grade or degraded quality).

(b) Insufficient oil in the crankcase.

(c) The pressure relief valve is malfunctioning.

(d) The pump liner is corroded.

(e) The filter is defective or clogged with debris.

(f) Oil leaks into the exhaust pipe.

Remedies:

(a) Use the correct grade of oil as specified by the manufacturer.

(b) Ensure the crankcase has the appropriate amount of oil.

(c) Repair or replace the pressure relief valve.

(d) Replace the corroded pump liner.

(e) Clean or replace the defective filter.

(f) Repair any leaks in the exhaust pipe.

4. The exhaust gas appears blue.

Causes:

(a) The cylinder head is cracked, allowing water to mix with the lubrication oil.

(b) The liner is damaged.

(c) The cylinder block is cracked.

(d) The head gasket is damaged.

(e) The water seal of the water pump is damaged.

Remedies:

(a) Repair or replace the cracked cylinder head.

(b) Replace the damaged liner.

(c) Replace the cracked cylinder block.

(d) Replace the damaged head gasket.

(e) Replace the damaged water pump seal.

5. The pressure gauge does not show a reading.

Causes:

(a) Insufficient oil in the crankcase.

(b) The oil pump is damaged.

(c) The pressure gauge is faulty.

(d) The spring in the oil pump’s relief valve is damaged.

Remedies:

(a) Ensure the correct amount of oil is applied to the crankcase.

(b) Repair the damaged oil pump.

(c) Repair or replace the faulty pressure gauge.

(d) Replace the damaged relief valve spring.

6. Sludge in lubricating oil.

Causes:

(a) The oil is black, often indicating blockage in the oil line.

(b) Oil is contaminated with dust, sand, or other impurities.

Remedies:

(a) Replace the contaminated oil and use the correct grade of oil.

(b) Prevent leaks and blockages in the oil line to avoid contamination.

Conclusion

Troubleshooting an engine lubricating system is essential for maintaining optimal engine performance and preventing potential damage. Addressing issues promptly can ensure the engine’s longevity and efficiencytimal engine performance and preventing potential damage. Addressing issues promptly can ensure the longevity and efficiency of the engine.